Simple, cost effective fork lift truck battery management

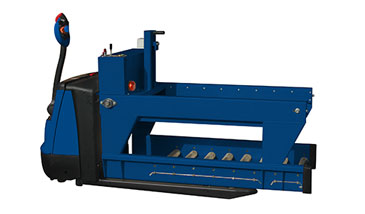

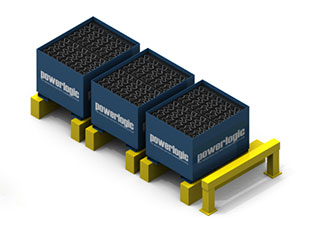

Traction batteries, as used in fork lift trucks and electric vehicles, are big and heavy. Changing them when they are discharged is a difficult and hazardous process. Using specifically designed handling systems speeds up the process and removes the hazards.

The type of system you require will depend on the number and type of vehicles you are operating and the degree of mechanical assistance you require. Available floor space is also a factor to consider.